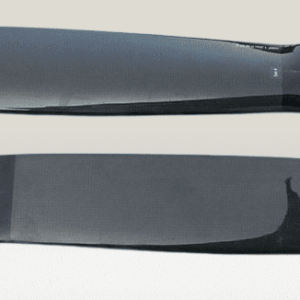

Description

Paramotor Top 80 Aluminum Exhaust – Performance, Durability, and Control in One Essential Upgrade

For paramotor pilots, every component matters. The Paramotor Top 80 Aluminum Exhaust stands as a transformative upgrade for both recreational and professional pilots. Engineered for optimal airflow, lightweight performance, and superior durability, this exhaust system enhances your Top 80 paramotor in every aspect, from acceleration to long-term reliability. Whether you are taking off from grass, sand, or water-adjacent terrain, this exhaust ensures your flight experience is smooth, safe, and exhilarating.

Premium Design Tailored for Pilots

The Paramotor Top 80 Aluminum Exhaust is meticulously crafted from aerospace-grade aluminum, balancing weight reduction and structural integrity. Aluminum’s natural resistance to corrosion and heat makes it ideal for paramotor engines that endure intense temperatures. Pilots will immediately notice the difference in handling and engine response.

-

Lightweight yet durable: Reduces overall weight without compromising strength.

-

Precision-engineered fit: Designed specifically for Top 80 engines.

-

Corrosion-resistant: Maintains performance even in humid or coastal environments.

-

Enhanced heat dissipation: Keeps engine components cooler during extended flights.

Unlike stock exhaust systems, this upgraded aluminum exhaust is designed with aerodynamic efficiency in mind. Its contours direct exhaust gases smoothly, resulting in improved thrust and less turbulence around the engine.

Why Performance Matters

Engine performance relies heavily on exhaust efficiency. With the Top 80 Aluminum Exhaust, airflow is optimized to reduce backpressure while maximizing thrust. This translates to smoother acceleration, reduced fuel consumption, and a more responsive engine.

-

Optimized airflow: Promotes consistent engine output.

-

Increased thrust efficiency: Achieve higher lift without additional strain on the engine.

-

Reduced engine vibration: Enhances comfort during long flights.

-

Fuel economy: Less wasted energy for more efficient flying sessions.

Transitioning to this aluminum exhaust immediately impacts the feel of your paramotor. Pilots report improved takeoff response and a noticeable reduction in engine heat, allowing longer and more comfortable flights.

Safety and Control

Safety is paramount in paramotoring, and exhaust design plays a critical role. Excessive heat, vibrations, or poorly directed exhaust gases can compromise pilot control. The Paramotor Top 80 Aluminum Exhaust addresses these concerns through precise engineering and robust materials.

-

Heat shield integration: Protects pilot and fuel lines from high temperatures.

-

Reduced engine wear: Aluminum construction lowers thermal stress on surrounding components.

-

Stable airflow: Minimizes turbulence around the engine frame.

-

Vibration reduction: Promotes precise handling during maneuvers.

By optimizing both safety and performance, this exhaust system offers pilots peace of mind. You can focus entirely on the experience of flight rather than engine concerns.

Ideal Use Cases

The Top 80 Aluminum Exhaust is not just an upgrade—it’s an essential tool for pilots seeking maximum performance. It suits a variety of paramotor flying styles, from casual recreational flying to competitive endurance flying.

-

Recreational pilots: Enjoy smoother flights with enhanced engine response.

-

Professional pilots: Benefit from durability and high-efficiency performance in extended sessions.

-

Cross-country flying: Optimized airflow ensures fuel efficiency and longer flight times.

-

Flight training: Lightweight and responsive design helps new pilots learn control more effectively.

Additionally, the aluminum exhaust adapts well to different environmental conditions, whether flying in coastal areas, high-humidity zones, or mountainous terrains.

Technical Specifications

Understanding the technical advantages of the Top 80 Aluminum Exhaust can help pilots make informed decisions. Each element of this exhaust system is designed to enhance flight experience, improve reliability, and extend the lifespan of your paramotor engine.

-

Material: Aerospace-grade aluminum

-

Weight: Approximately 1.2 kg (varies slightly by model)

-

Engine Compatibility: Top 80 paramotor engines

-

Finish: Anodized for corrosion resistance

-

Heat Shield: Integrated for pilot protection

-

Mounting: Bolt-on installation with precision alignment

The lightweight design contributes to better weight distribution, improving both stability and maneuverability during flights. Even under extended operation, the aluminum construction maintains consistent performance without warping or fatigue.

Installation Guide

Installing the Paramotor Top 80 Aluminum Exhaust is straightforward but requires careful attention to ensure optimal performance and safety.

-

Preparation: Ensure your engine is cooled and workspace is clean. Remove the stock exhaust carefully.

-

Positioning: Align the aluminum exhaust with engine mounts.

-

Secure Bolts: Use supplied bolts and torque to manufacturer’s specifications.

-

Heat Shield Adjustment: Ensure shield is correctly positioned to protect pilot and engine components.

-

Testing: Start the engine to verify fit, sound, and airflow. Adjust if necessary.

Transitioning from stock to aluminum exhaust can feel immediately noticeable in engine response and overall flight handling. Always refer to professional guides or consult experienced technicians if unsure.

Performance Highlights

Pilots will quickly notice the tangible benefits once installed. The Top 80 Aluminum Exhaust delivers consistent power and reliability across various conditions.

-

Smoother takeoff: Immediate response with less engine lag.

-

Quieter operation: Aluminum reduces resonance compared to stock exhaust.

-

Longer engine life: Lower thermal stress preserves engine components.

-

Weight advantage: Enhances agility and maneuverability.

This upgrade transforms the flying experience by merging performance, durability, and safety into one component.

Maintenance and Longevity

Aluminum is inherently durable, but proper maintenance ensures your exhaust lasts for years. Simple steps prevent corrosion and maintain peak performance.

-

Regular inspection: Check for cracks, dents, or loose bolts.

-

Clean gently: Use mild detergents to remove soot or debris.

-

Check alignment: Ensure exhaust remains properly positioned after repeated flights.

-

Monitor engine performance: Reduced airflow issues may indicate the need for servicing.

By maintaining the exhaust, pilots ensure a long lifespan and continuous performance improvement.

Why Pilots Trust the Paramotor Top 80 Aluminum Exhaust

From design to installation, every aspect of this exhaust system is engineered for reliability, safety, and performance. Pilots consistently report smoother flights, longer engine life, and more responsive handling. Lightweight, durable, and corrosion-resistant, this exhaust is a tangible upgrade that makes every paramotor flight safer and more enjoyable.

Summary

The Paramotor Top 80 Aluminum Exhaust is more than a replacement part. It is a high-performance upgrade that enhances engine efficiency, pilot safety, and flight enjoyment. With precision engineering, lightweight aluminum construction, and attention to airflow dynamics, this exhaust is suitable for recreational pilots, professionals, and flight trainers alike.

Whether you are taking off for a short scenic flight or an extended cross-country adventure, the Top 80 Aluminum Exhaust ensures your engine performs at its peak, every time. Upgrade your paramotor experience today and feel the difference in performance, control, and durability.

Highlighted Features at a Glance:

-

Aerospace-grade aluminum construction

-

Lightweight design for better maneuverability

-

Optimized airflow for enhanced thrust

-

Corrosion-resistant anodized finish

-

Heat shield for pilot and engine safety

-

Simple bolt-on installation

-

Reduced vibration and smoother operation

-

Ideal for recreational, professional, and training use

Safety and Control: Protecting Pilots While Maximizing Performance

Flying a paramotor is exhilarating, but safety and control remain paramount. The Paramotor Top 80 Aluminum Exhaust is engineered with pilot protection and stable handling at the forefront. Every detail—from material selection to design contours—contributes to a safer, more predictable flight experience.

Enhanced Thermal Protection

Exhaust heat is one of the main concerns for pilots. Traditional exhaust systems can transfer excessive heat to surrounding components, posing a risk to both engine and pilot. The aluminum construction of this exhaust provides superior heat dissipation, lowering the risk of burns and reducing thermal stress on the engine.

-

Heat shield integration: Strategically positioned shields deflect heat away from critical areas.

-

Reduced engine temperature: Aluminum efficiently disperses heat, preserving internal engine parts.

-

Pilot protection: Minimizes direct exposure to high-temperature surfaces during handling and flight.

Stable Engine Performance for Reliable Control

Control in paramotoring begins with predictable engine response. The Top 80 Aluminum Exhaust reduces turbulence and backpressure, resulting in smoother throttle transitions. Pilots can rely on consistent engine behavior, which directly improves maneuverability and flight precision.

-

Reduced vibration: Aluminum absorbs and disperses vibrations, making handling more comfortable.

-

Consistent airflow: Promotes stable thrust, reducing sudden changes that could affect flight balance.

-

Improved takeoff response: Quick, controlled lift-offs enhance pilot confidence in various terrains.

Durability That Supports Safety

A robust exhaust system is not only about performance—it’s a critical safety component. Aluminum’s strength and corrosion resistance prevent cracks, leaks, and premature wear that could compromise control mid-flight. This reliability ensures that pilots can focus on navigation and maneuvering rather than engine concerns.

-

Long-lasting materials: Aluminum withstands heat cycles without deforming.

-

Corrosion resistance: Maintains integrity in humid, coastal, or high-altitude conditions.

-

Impact tolerance: Slight bumps or vibrations during transport or landing do not compromise safety.

Pilot-Centric Design Features

Beyond structural advantages, this exhaust includes subtle design enhancements that further improve safety and control. Its shape channels exhaust gases away from the pilot, reducing the chance of accidental contact or heat exposure. Mounting points are reinforced to prevent loosening during flight, ensuring the exhaust remains stable even during aggressive maneuvers.

-

Exhaust gas deflection: Directs hot gases away from pilot and fuel lines.

-

Secure mounting system: Maintains exhaust alignment under all flight conditions.

-

Aerodynamic design: Minimizes turbulence around the frame, enhancing control during turns and climbs.

Summary: Safety Meets Performance

By combining advanced materials, precise airflow design, and protective features, the Paramotor Top 80 Aluminum Exhaust elevates both pilot safety and control. Reduced engine vibrations, predictable airflow, and thermal protection collectively create a reliable, high-performance system that allows pilots to fly confidently and focus on the joy of flight.smith miniplane

Innovative Design: Engineering Excellence for Top 80 Paramotors

The Paramotor Top 80 Aluminum Exhaust is more than a simple replacement part—it is a carefully engineered component designed to maximize performance, reliability, and pilot satisfaction. Every curve, weld, and surface is thoughtfully created to enhance airflow, reduce weight, and maintain durability.

Aerospace-Grade Aluminum Construction

At the heart of the exhaust’s design is premium aluminum, selected for its exceptional strength-to-weight ratio. This choice allows the exhaust to remain lightweight without compromising structural integrity. Aluminum also provides natural corrosion resistance, ensuring that the exhaust performs consistently even in humid or coastal flying conditions.smith miniplane

-

Lightweight: Reduces overall paramotor weight for improved maneuverability.

-

Durable: Withstands repeated thermal cycles without warping or fatigue.

-

Corrosion-resistant: Maintains its finish and performance over time.

Precision Engineering for Optimal Fit

The exhaust is specifically designed for the Top 80 paramotor engine, guaranteeing a perfect fit without the need for modifications. Precision engineering ensures that all mounting points align accurately, preventing vibrations, leaks, or misalignment during flight.parasail with engine

-

Bolt-on installation: Quick and secure mounting with minimal adjustments.

-

Exact alignment: Maintains engine performance and reduces stress on surrounding components.

-

Integrated heat shield: Designed to protect pilot and engine components from high temperatures.

parasail with engine Aerodynamic Flow Optimization

One of the most critical aspects of exhaust design is airflow management. The Top 80 Aluminum Exhaust features smooth, contoured surfaces that reduce turbulence and enhance exhaust gas expulsion. This aerodynamic approach contributes to smoother engine operation, increased thrust, and improved fuel efficiency.

-

Smooth internal channels: Minimize backpressure for better engine response.

-

Gas deflection design: Directs exhaust safely away from the pilot and frame.

-

Optimized airflow: Improves overall engine efficiency and longevity.

Modern Aesthetic Meets Functionality

Beyond performance, the exhaust’s sleek anodized finish offers a professional, modern appearance. Pilots can enjoy both visual appeal and functional advantages, as the anodized surface adds an extra layer of protection against scratches, corrosion, and wear.

-

Anodized finish: Durable and visually appealing.

-

Smooth contours: Reduce the risk of snagging on clothing or equipment.

-

Compact design: Preserves the paramotor’s streamlined profile.

Pilot-Focused Design Features

Every element of the Paramotor Top 80 Aluminum Exhaust is tailored to improve the flying experience. The lightweight construction reduces strain during transport, while the aerodynamic shape enhances handling and control in the air. The integrated heat shield and secure mounting system prioritize pilot safety without sacrificing performance.parasail with engine

-

Reduced weight: Easier handling on the ground and in the air.

-

Vibration absorption: Aluminum disperses engine vibrations for smoother operation.

-

Safety-first layout: Prevents accidental contact with hot surfaces and fuel lines.

Summary: Form Meets Function

The Top 80 Aluminum Exhaust exemplifies the perfect balance between design elegance and engineering practicality. Lightweight, durable, and aerodynamically optimized, it enhances engine performance, improves pilot safety, and elevates the overall paramotor experience. Every detail reflects a commitment to quality, functionality, and reliability, making this exhaust an essential upgrade for Top 80 paramotor owners.

How to Use: Installing and Maximizing Your Paramotor Top 80 Aluminum Exhaust

Using the Paramotor Top 80 Aluminum Exhaust is straightforward, but understanding proper installation and handling ensures maximum performance, durability, and pilot safety. This section guides both new and experienced pilots through step-by-step instructions, tips for optimal operation, and safety precautions.

Step 1: Preparing for Installation

Before installing the exhaust, ensure the engine is completely cooled. Working on a hot engine can be dangerous and may damage components. A clean workspace and the correct tools will make installation smooth and efficient.

-

Cool down: Always allow the engine to cool to avoid burns.

-

Gather tools: Typically, wrenches, screwdrivers, and torque wrenches are needed.

-

Inspect components: Check the exhaust for any shipping damage or debris before installation.

-

Remove old exhaust: Carefully unbolt the stock exhaust, keeping mounting hardware for reference.

Taking the time to prepare ensures that installation is safe, accurate, and free from unnecessary adjustments later.

Step 2: Aligning the Exhaust

Position the Top 80 Aluminum Exhaust carefully against the engine’s mounting points. Precise alignment is crucial for maintaining airflow efficiency, reducing vibrations, and ensuring pilot safety.

-

Mounting points: Ensure all bolt holes match the engine’s designated mounts.

-

Check fitment: Gently place the exhaust in position without fully tightening bolts.

-

Heat shield orientation: Confirm that the integrated heat shield protects nearby components and pilot contact points.

Proper alignment is key for performance. Misaligned installation can lead to vibrations, exhaust leaks, or reduced engine efficiency.

Step 3: Securing the Exhaust

Once aligned, fasten the exhaust bolts gradually and evenly. Tightening bolts in the correct sequence prevents stress on the aluminum, preserves the finish, and ensures a secure, vibration-free installation.

-

Use manufacturer-recommended torque: Over-tightening can damage threads or deform aluminum.

-

Check for stability: Ensure the exhaust sits firmly without movement.

-

Inspect clearance: Confirm that no parts are contacting the frame, lines, or pilot harness.

Even small errors in securing the exhaust can compromise both safety and performance, so attention to detail is essential.

Step 4: Pre-Flight Testing

Before taking off, perform a series of checks to verify correct installation and safe operation.

-

Engine start: Observe exhaust alignment and ensure no unusual vibrations occur.

-

Throttle response: Check for smooth acceleration and consistent performance.

-

Visual inspection: Look for any exhaust leaks or loose hardware.

Pre-flight testing allows pilots to correct any minor issues before taking to the air, ensuring a safer and more predictable flight.

Step 5: In-Flight Considerations

Once installed, the Paramotor Top 80 Aluminum Exhaust requires no special operation, but pilots should remain aware of engine behavior.

-

Monitor engine temperature: Aluminum dissipates heat efficiently, but high-performance flights may still produce elevated temperatures.

-

Observe airflow response: The optimized exhaust should provide smooth thrust and responsive handling.

-

Check vibration levels: Slight reductions in engine vibration are normal; significant changes may indicate misalignment.

By staying attentive during initial flights, pilots can fully benefit from the enhanced performance, control, and safety offered by the aluminum exhaust.

Maintenance for Continued Use

Proper maintenance ensures longevity and sustained performance of your exhaust system.

-

Routine inspection: Check bolts, heat shields, and aluminum surfaces for wear or corrosion.

-

Cleaning: Use mild soap and water to remove soot or dirt; avoid harsh abrasives.

-

Realignment: Verify exhaust remains securely mounted after extended flights or transport.

-

Performance monitoring: Watch for changes in engine response, as this can indicate maintenance needs.

Summary: Safe and Effective Usage

Using the Paramotor Top 80 Aluminum Exhaust correctly combines careful installation, attentive pre-flight checks, and regular maintenance. Pilots benefit from improved engine performance, enhanced thrust, reduced vibrations, and superior safety. By following these steps, the exhaust becomes a reliable, long-term upgrade that enhances every flight experience.

Frequently Asked Questions (FAQ) – Paramotor Top 80 Aluminum Exhaust

Pilots often have questions about installation, compatibility, performance, and maintenance. This FAQ addresses the most common concerns, helping you make an informed decision about the Top 80 Aluminum Exhaust.

Q1: Is the Top 80 Aluminum Exhaust compatible with all Top 80 engines?

A: Yes, the exhaust is specifically engineered for Top 80 paramotor engines. However, pilot should always verify model year and engine configuration to ensure a perfect fit. Precision engineering guarantees smooth installation and optimal performance.

Q2: Can I install it myself, or should I seek professional help?

A: Installation is straightforward for those familiar with paramotor maintenance and basic tools. Step-by-step guidance ensures safe mounting, proper heat shield positioning, and correct alignment. First-time installers or pilots uncertain about torque specifications may prefer professional assistance to maximize safety and performance.

Q3: Does it affect engine noise levels?

A: Yes. Aluminum construction helps reduce resonance compared to stock exhausts, providing a smoother and slightly quieter operation. While it does not act as a silencer, many pilots report more comfortable sound levels during flights.

Q4: How does the exhaust impact engine performance?

A: The optimized airflow reduces backpressure, improving thrust efficiency, acceleration, and overall engine response. Pilots experience smoother takeoffs, better maneuverability, and improved fuel economy, particularly during long flights.

Q5: Is the exhaust durable in various environmental conditions?

A: Absolutely. Aerospace-grade aluminum is naturally corrosion-resistant and capable of withstanding high temperatures. The anodized finish offers extra protection, making it suitable for humid, coastal, or high-altitude environments.

Q6: How should I maintain the aluminum exhaust for longevity?

A: Routine maintenance includes:

-

Inspecting bolts, heat shields, and surfaces for wear or damage.

-

Cleaning gently with mild soap and water to remove soot or debris.

-

Checking alignment and mounting stability after extended flights.

-

Monitoring engine performance for any unusual changes.

Regular care ensures long-term durability, consistent performance, and continued pilot safety.

Q7: Will it affect fuel consumption?

A: Yes. By reducing engine backpressure and improving thrust efficiency, the exhaust can enhance fuel economy slightly. Pilots may notice more efficient climbs and longer flight times without increasing fuel load.

Q8: Can it be used for professional training or competitive flying?

A: Definitely. The lightweight construction, aerodynamic design, and thermal management make it ideal for recreational pilots, flight instructors, and professionals who demand consistent performance and safety over extended flights.paraplane powered parachute

Q9: What should I do if I notice vibrations or unusual noise?

A: Minor reductions in vibration are normal due to aluminum’s damping properties. Significant or new vibrations may indicate misalignment or loose bolts. Inspect the exhaust, verify mounting torque, and adjust alignment as necessary. Professional assistance is recommended if the issue persists.paraplane powered parachute

Q10: How long can I expect the exhaust to last?

A: With proper care and regular maintenance, the Top 80 Aluminum Exhaust can last multiple flying seasons without degradation, maintaining performance, safety, and reliability throughout its lifespan.

Reviews

There are no reviews yet.